Cnc Beam Drill Line Key

�.. Although this machine is marketed for the Structural fabricators, I knew immediately it would work well for drilling truck frames. The accuracy & repeatability have ensured the assembly without error. The Avenger drills a set of channels for one truck in less than one 2 hours; when we did this manually, it would take 16 hours. This machine has increased our productivity & profitability hands down!..�

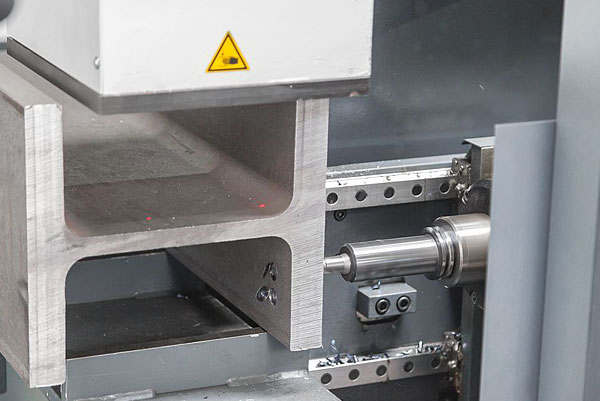

GSS Machinery gets asked often by our customers which drill bits to use. Should they use twist drill bits, or insert bits. As this will help our customers be more competitive and more profitable, it is our number one goal to reduce the cost per hole. But it is crucial that they understand all of their options. Insert Drill Bit (Spade Drill Bit). Advantages